Technology based on artificial vision and AI algorithms that provide fast, real-time information about machine status, allowing decisions and

actions to be taken at an early stage of failure, generating considerable savings.

- Particle counting according to ISO standard > 4 microns

- Classifies particles in 6 ranges (>4, >6, >14, >21, >32, >70 μm)

- Oil degradation (OilWear C120 & S120)

- Shape analysis (OilWear S100 & S120)

- Discrimination and counting of air bubbles

- Fluid image storage

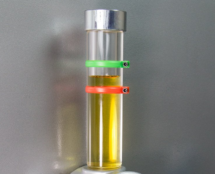

Types of fluids:

Hydraulic fluids and lubricants

Fuels

Mineral and synthetic oils

Coolants

Cutting fluids

Aqueous solutions

Glycols

Cleaning fluids

Water

Benefits:

Classification and counting of particles larger than 4 microns in 6 ranges

Provides early information on machine condition, up to 7 times earlier than other

technologies

Provides fast and reliable information on fluid contamination

Extends fluid life and reduces machine downtime

Recognizes and classifies particles larger than 20 microns by wear type helping to

identify root cause

Integrates OilHealth technology that provides information on oil degradation and

contamination

Simple installation

Full integration with SCADA/PC/PLC via digital communications for easy interpretation

Self-calibrating and self-diagnosing technology